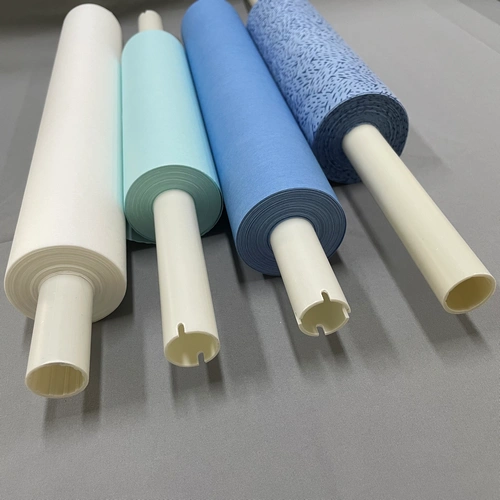

SMT Stencil Wiping Rolls | 56g/68g for Solder Paste & Glue

Dual-layer structure of cellulose and polyester (one side cellulose, one side polyester). Low-linting, highly absorbent, with antistatic properties, high tensile strength, and good solvent compatibility. Primarily used in solder paste printers to clean solder paste, red glue, and other residues. Produced in a Class 1,000 or Class 10,000 cleanroom.

Specifications

| Model | Size | Core | Packaging | Material | Basis Weight | Pattern | Process | Color |

|---|---|---|---|---|---|---|---|---|

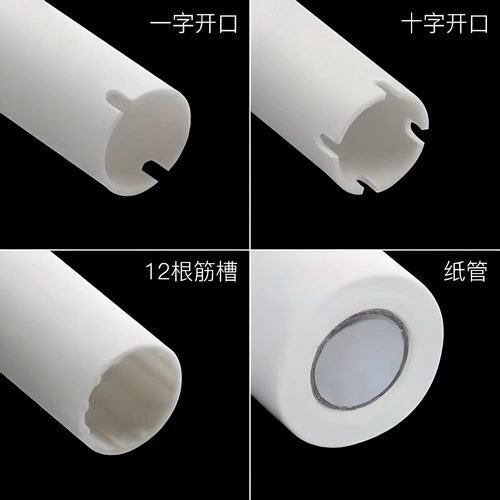

| SMT-Plain-56g | 300mm x 10m | ID: 20mm, Length: 530mm, with notches on both ends | 1 Roll/Bag, Vacuum-Sealed | 55% Cellulose + 45% Polyester | 56g | Plain Weave | Air-laid + Spunlace | White |

| SMT-Plain-68g | 300mm x 10m | ID: 20mm, Length: 530mm, with notches on both ends | 1 Roll/Bag, Vacuum-Sealed | 55% Cellulose + 45% Polyester | 68g | Plain Weave | Air-laid + Spunlace | White |

| Customizable Sizes | Customizable Cores |

Unsure how to choose basis weight, etc.? Refer to our Cleanroom Consumables Selection Guide.

Common Specifications

| Automatic Printer | Roll Width/mm | Roll Length/m | Core Length/mm | Core ID/mm |

|---|---|---|---|---|

| JUKI | 260 | 15 | 270 | 38 |

| JUKI | 400 | 8 | 408 | 38 |

| JUKI | 450 | 10 | 470 | 19.6 |

| Panasonic SP18 | 350 | 10 | 380 | 38 |

| Hitachi | 300 | 10 | 360 | 30 |

| FUJI | 250 | 10 | 355 | 19.5 |

| FUJI | 500 | 15 | 500 | 26 |

| FUJI | 610 | 12 | 625 | 20 |

| MINAMI | 270 | 10 | 290 | 8 |

| MINAMI | 350 | 10 | 410 | 8 |

| MPM | 250/300/330/350/400 | 10 | 455 | 19.5 |

| EKRA | 300/400 | 10 | 400 | 14.5 |

| DEK | 250/300/400/490/500/510 | 10 | 530 | 20 |

| KME | 480 | 20 | 480 | 38 |

| GKG | 300/400 | 10 | 410 | 20 |

| Desen | 300 | 10 | 410 | 20 |

| YAMAHA | 350 | 10 | 360 | 25.5 |

| YAMAHA | 400 | 10 | 420 | 25.5 |

Applications

Designed for automated SMT solder paste printers, these rolls are installed in the automatic cleaning systems of major printer brands (like DEK, MPM, JUKI, Panasonic, etc.). They are used to periodically wipe the underside of the stencil, efficiently removing residual solder paste, red glue, and other contaminants. This effectively prevents printing defects such as bridging and insufficient solder caused by clogged apertures, ensuring high-quality solder joints.