50x | Polyester Cleanroom Wipes 110g/120g Rib Knit 1009SLE

PICOWIPE 50x series polyester cleanroom wipes, also known as the widely used 1009SLE industrial wipe, are characterized by their cost-effectiveness. The rib knit pattern offers a lower risk of scratching (the interlock knit version of this style is the 10x series). Available with laser sealed or knife-cut edges; laser sealing offers a lower edge shedding rate. Commonly used in Class 1,000 to Class 10,000 cleanrooms and general industrial environments. Poor absorbency; not suitable for cleaning liquid spills.

Specifications

| Model | Size (inches) | Packaging | Edge | Material | Basis Weight | Pattern | Construction | Color |

|---|---|---|---|---|---|---|---|---|

| 501a | 9x9" | 150 pcs/bag | Knife-Cut | 100% Polyester | 110g | Rib Knit | Double Knitted | White |

| 503a | 6x6" | 150 pcs/bag | Knife-Cut | 100% Polyester | 110g | Rib Knit | Double Knitted | White |

| 505a | 4x4" | 600 pcs/bag | Knife-Cut | 100% Polyester | 110g | Rib Knit | Double Knitted | White |

| 501b | 9x9" | 150 pcs/bag | Knife-Cut | 100% Polyester | 120g | Rib Knit | Double Knitted | White |

| 503b | 6x6" | 150 pcs/bag | Knife-Cut | 100% Polyester | 120g | Rib Knit | Double Knitted | White |

| 505b | 4x4" | 600 pcs/bag | Knife-Cut | 100% Polyester | 120g | Rib Knit | Double Knitted | White |

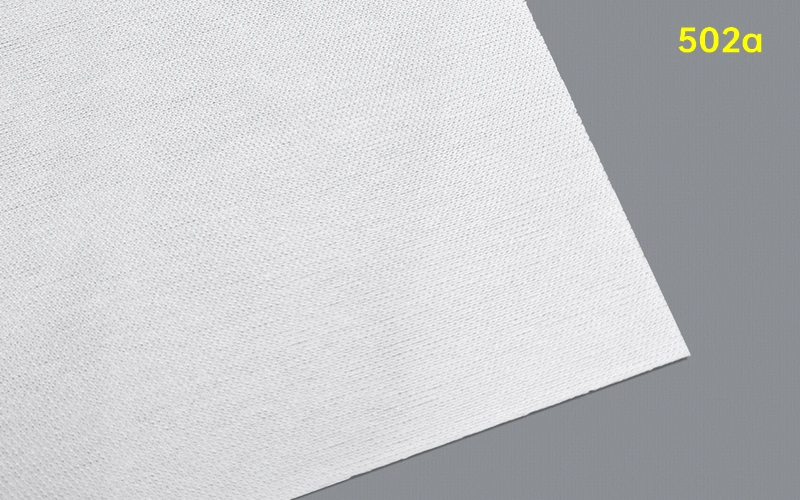

| 502a | 9x9" | 150 pcs/bag | Laser | 100% Polyester | 110g | Rib Knit | Double Knitted | White |

| 504a | 6x6" | 150 pcs/bag | Laser | 100% Polyester | 110g | Rib Knit | Double Knitted | White |

| 506a | 4x4" | 600 pcs/bag | Laser | 100% Polyester | 110g | Rib Knit | Double Knitted | White |

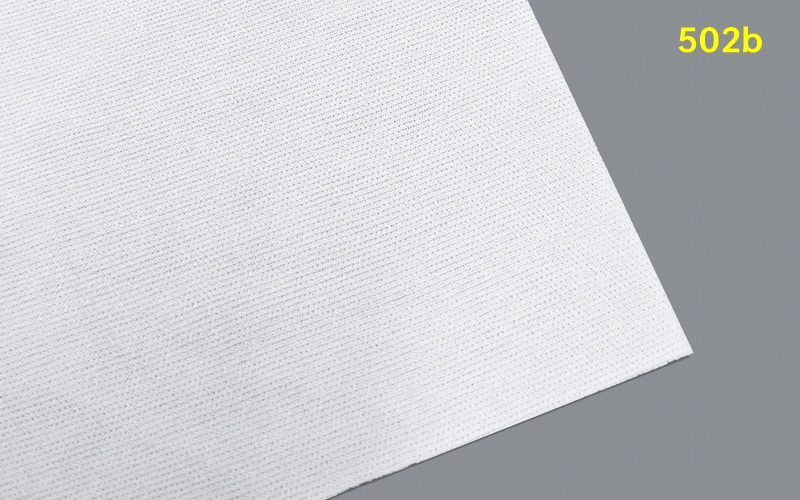

| 502b | 9x9" | 150 pcs/bag | Laser | 100% Polyester | 120g | Rib Knit | Double Knitted | White |

| 504b | 6x6" | 150 pcs/bag | Laser | 100% Polyester | 120g | Rib Knit | Double Knitted | White |

| 506b | 4x4" | 600 pcs/bag | Laser | 100% Polyester | 120g | Rib Knit | Double Knitted | White |

| Customizable | Laser / Knife-Cut |

Unsure how to choose basis weight, edge type, etc.? Refer to our Cleanroom Consumables Selection Guide.

Applications

Primarily used for the cleaning and maintenance of industrial machinery in general environments, and for the pre-treatment of hardware, plastic parts, and various components prior to assembly. It effectively removes surface dust and oil stains from most industrial materials without causing damage, laying a clean foundation for subsequent critical processes like spraying, plating, and bonding. It is the first step in controlling cost and quality in streamlined production.